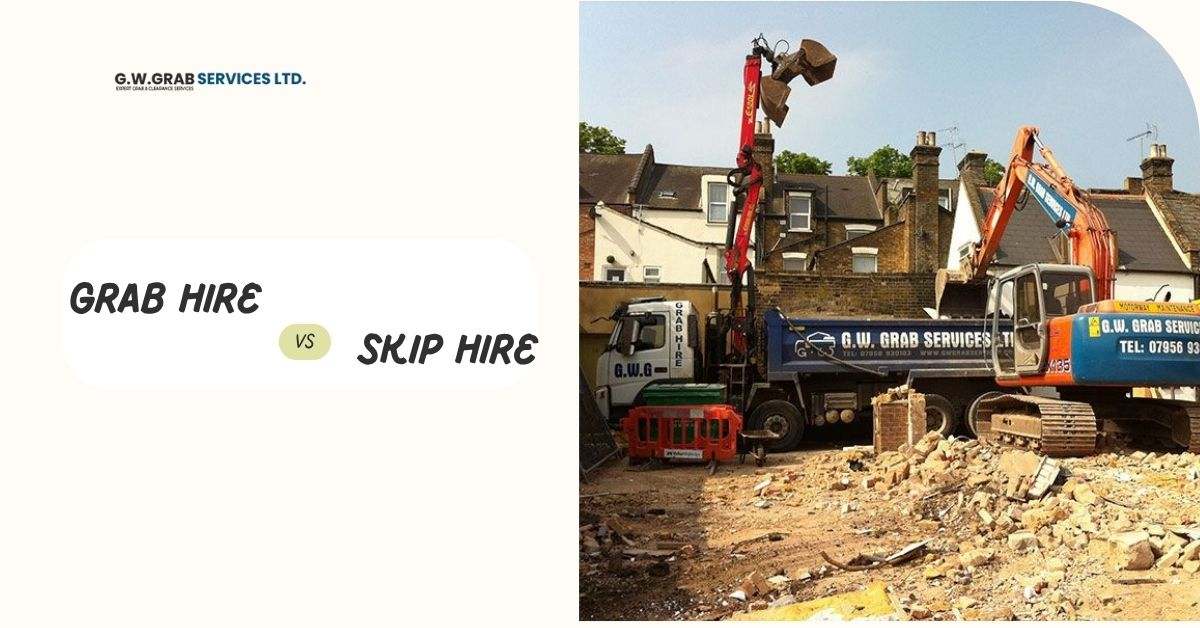

Waste management is like a battle, particularly when you have to handle large amounts of waste due to renovations, landscaping projects, or construction sites. Piles of rubble, soil, and debris don’t just take up valuable space; they slow down your entire project. Traditional skip hire has been the go-to solution for years, but it comes with its own set of problems. You have to wait days for delivery, find space for its placement, and sometimes even apply for permits to place it in a public place. It is where local grab hire cuts through all of that hassle and gets your waste removed the same day you need it.

Here is what makes this local grab hire service so efficient and why it could be the ideal solution to your next project.

Speed that keeps your project moving

Time matters when you are in the middle of a project. Same-day grab hire availability means you don’t have to plan weeks or let waste pile up.

If you search “grab hire near me”, you will get companies that can respond within hours:

- Get the collection scheduled within the same working day

- Quick loading process that takes just 10-15 minutes

- Immediate site clearance on time

- Flexible booking with your timeline

This speed helps commercial jobs, especially where delays incur costs and staying on schedule protects your budget.

Local grab hire brings accessibility where other services can’t reach

Not every property has the luxury of a wide driveway or open front garden. Properties with narrow driveways, locked gates, or tricky access have always had trouble with skip placement. The grab arm fixes this by reaching up to 8 meters, so the vehicle parks on the public road while collecting waste from your property.

Efficient waste removal works even in difficult spots. You skip the hassle of getting street permits or dealing with annoyed neighbours about blocked access. Our grab hire services make the whole process simple and stress-free, offering quick and professional waste collection where skips just can’t go.

Versatility for every type of project

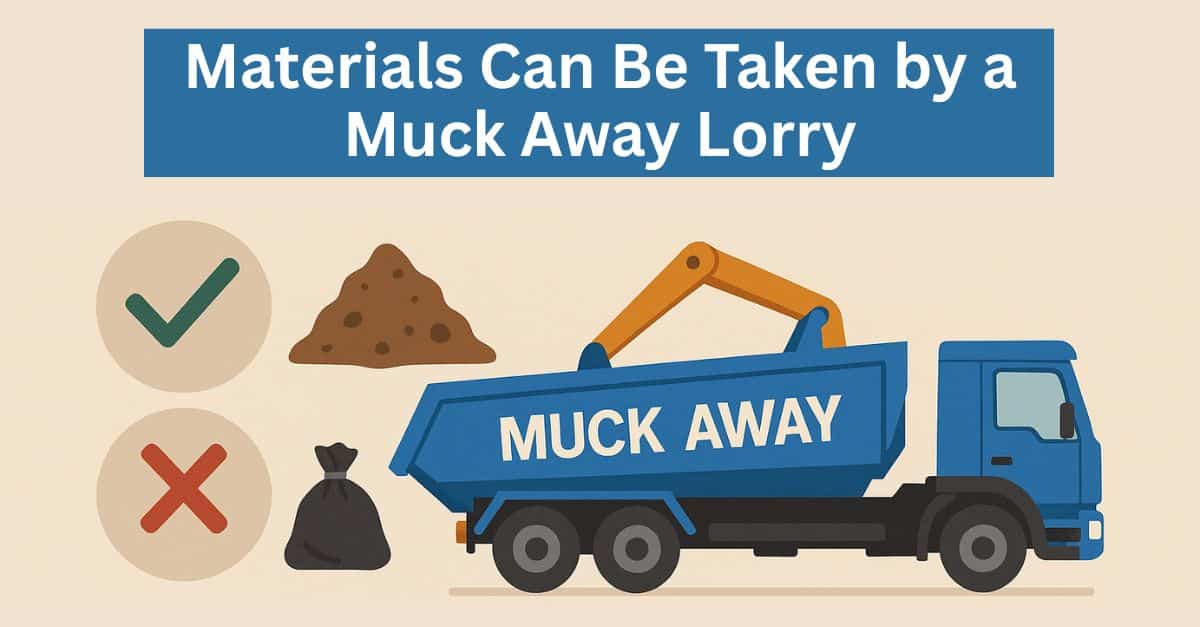

A local waste management company with grab hire handles a wide range of materials. Whether you are removing domestic and commercial waste, these vehicles take everything from soil and rubble to green waste and building debris:

- Soil, clay, and dug-up materials from the groundwork

- Concrete, bricks, and hardcore from demolition

- Garden waste like branches, turf, and plants

- Mixed building debris and renovation waste

- Topsoil from landscaping works

This flexibility makes site clearance services far more practical. A single grab lorry collects 16 tonnes in one trip, equivalent to approximately two large skips, making it ideal for larger jobs that require quick waste removal solutions.

Why local grab hire providers make a real difference

Working with a local grab hire company offers significant advantages for your project. Local firms are familiar with the local area rules and can reach you promptly. Their reputation is on retaining local customers, and hence, you get a better service. When your provider is operating nearby, it takes a shorter time to respond.

Do you need urgent collection before the weather changes, or is an inspection scheduled? You can make last-minute bookings and avail of services that larger national organisations are unable to coordinate. You also build a relationship, and it will offer you better tips over time.

Making waste removal work for you

The concept of local grab hire services has changed waste collection by prioritising speed and convenience for the customers. Gone are the days of working around skip deliveries and access issues. Now, you have a service that is flexible to your specifications. Whether you are clearing a small garden or managing a large building site, the right help makes everything run smoothly.

Contact GW Grab Services today and discover how the right waste collection can help keep your project on schedule without the usual headaches.